DURABILITY

ADHESION

SUPER ADHESION 5

UNIFIED COATING

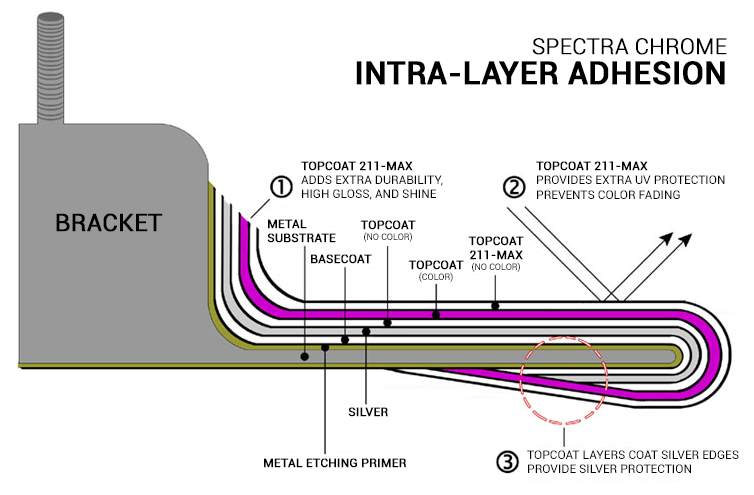

Although Spectra Chrome is composed of several layers, the final finish behaves as a single, unified coating. The advanced chemistry performance of Spectra Chrome provides intra-layer adhesion and unmatched durability; no matter the application. This steel bracket is a perfect demonstration of the multiple layers that comprise the final Spectra Chrome finish.

As with any “raw” metal surface, the bracket was first coated with a metal etching primer to seal the metal before painting. Using etching primers and other surface preparation techniques is explained in detail in our all-new Training Online.

Spectra Chrome Basecoat, Metal Spray, and Topcoat 311 (tinted purple) is applied next, followed by our ultra-durable Topcoat 211-MAX (no color), “sealing” the final finish and providing extreme durability and UV resistance.

The finished bracket is then gouged with a screwdriver; down through all of the layers and into the “raw” metal surface underneath. Adhesive tape is then applied over the damaged area – watch how none of the exposed edges of the Spectra Chrome finish can be removed past the point of the induced gouging!